Current Sensor Mounting on PCB with CTS Technology

Precise sensor mounting on printed circuit boards (PCBs) is crucial for reliable measurements and optimal performance. Our CTS sensor solutions provide high-quality components and easy integration to meet industrial demands. With innovative mounting techniques and durable materials, we ensure a secure and long-lasting connection between sensor and PCB. This guarantees the highest measurement accuracy and enhances overall system performance.

Current Sensor Mounting on PCB with CTS Technology

|

Precise sensor mounting on printed circuit boards (PCBs) is crucial for reliable measurements and optimal performance. Our CTS sensor solutions provide high-quality components and easy integration to meet industrial demands. |

With innovative mounting techniques and durable materials, we ensure a secure and long-lasting connection between sensor and PCB. This guarantees the highest measurement accuracy and enhances overall system performance. |

Product Resources

Features

- Open Loop Hall-Effect Measurement

- Current sensors for mounting on power PCB electronics

- Large range of currents up to 1200 A with 2.5% linearity error over lifetime

- Optional ASIL C functional safety standard

- Non-intrusive sensing (no losses)

- Low hysteresis and High Permeability

- Low Thermal Offset and Low Thermal Sensitivity

- Unipolar 5V DC power supply and Fully ratio-metric

- Engineering, prototyping, and high-volume manufacturing

- Based on platform design for "the first time right" design and manufacturing

Hall-effect open-loop current sensors have the innate ability to isolate and convert complex signals such as AC and DC currents. This type of isolation is a common choice for inverter modules or battery monitoring, however, many of these board designs feature a vertical current sensor design. A vertical design can take up more space in the unit and requires the busbar to go around the PCB design.

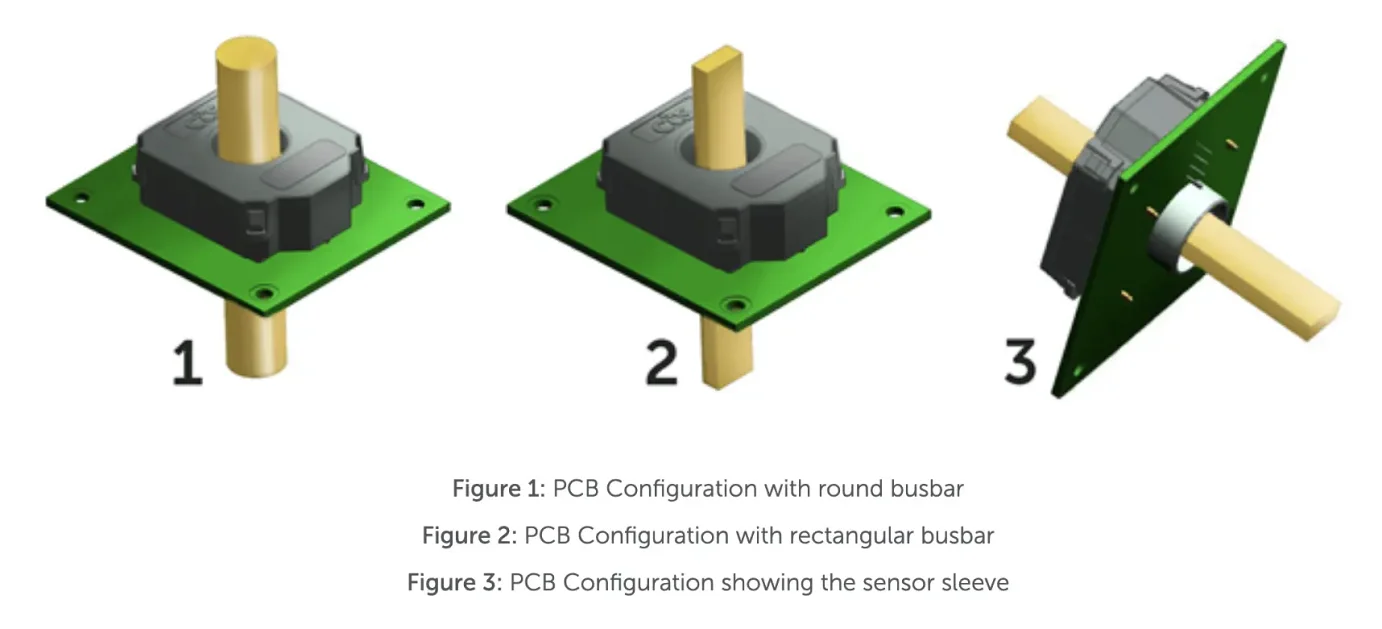

CTS's current sensor features a through-hole configuration, enabling flush mounting directly onto a driver board. This design enables the busbar to pass through the PCB, establishing a direct connection between the power source and the motor while optimizing space efficiency. Additionally, the versatile design can accommodate various busbar geometries, ensuring compatibility with different system configurations and ultimately, reducing costs. This design supports functional safety options to ensure quality in automotive and industrial applications.

Applications

- Material Handling

- Industrial Macheinery

- Electrical Power Steering

- Light Automotive

- AC/DC Converters

- DC Link

- Inverters

- Battery Management

- Motor controls

- Starter Generators

- Converters

- Charging systems

We’ll be happy to advise you on the powerful current sensors from CTS and support you with customized solutions tailored to your application.