The need to sense speed and position of ferrous gears occurs in numerous applications. In order to detect the passing gear-teeth with a Hall Effect sensor it is necessary to provide a source of magnetic energy. The simple way to do this is to arrange a permanent magnet so that the axis of magnetization is pointing toward to surface of the gear-teeth.

MLX90217

Continuously adapting gear-tooth sensor

The MLX90217 is a continuously adapting digital gear-tooth sensor designed for use in automotive camshaft sensing as well as other speed sensing applications.

Comparative table

| Geartooth/ Speedsensors | |||||

|---|---|---|---|---|---|

| Product | Function | Output | Benefits | Package | Datasheet |

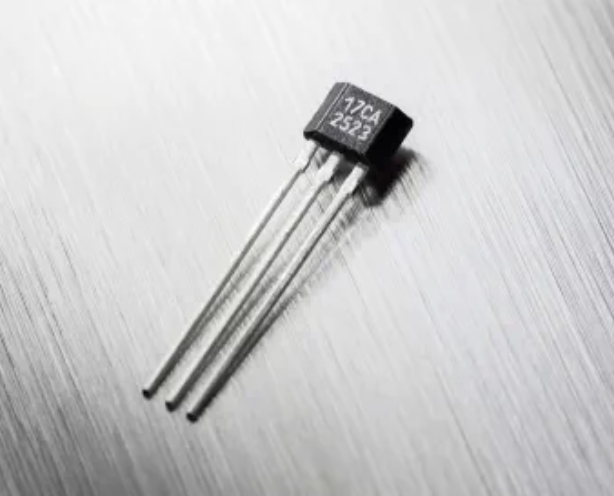

| MLX90217 | Speed Geartooth, Camshaft Sensing | Open Collector Swith | VDD range from 3,5V to 24V, Factory progammable parameters, Hyteresis from 1,8 to 10mT, Hysteresis 3,8 to 12mT | 3L TO-92 | Datasheet |

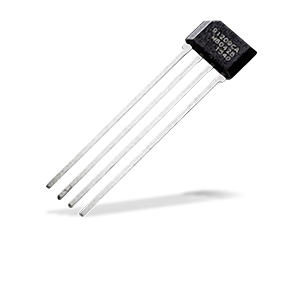

| MLX90254 | Differential Speed, Crankshaft Sensing | Open Drain Switch | VDD range from 4V to 24V, Simultaneous Speed and Position Sensing, Large Airgap range, Detection frequency 15Hz to 30Hz | Thin 4L TO-92 flat | Datasheet |

| MLX92232 | Programmable 3-wire Hall-effect sensor IC | Is the first end-of-line programmable sensor IC in a family of high accuracy devices. | TO92-3L | Datasheet | |

| MLX92242 | 2-wire Hall-effect switch/latch IC | Wide operating voltage range: from 2.7 V to 24 V | TO92-3L | Datasheet | |